Your Consulting Partner

Quality Material for Steel

JI Steel is one of the China top manufacturer of copper mould tube for continue casting machine.

According to different requirements of our customers,

design and manufacture all kind of types of copper mould tubes.

Main Products

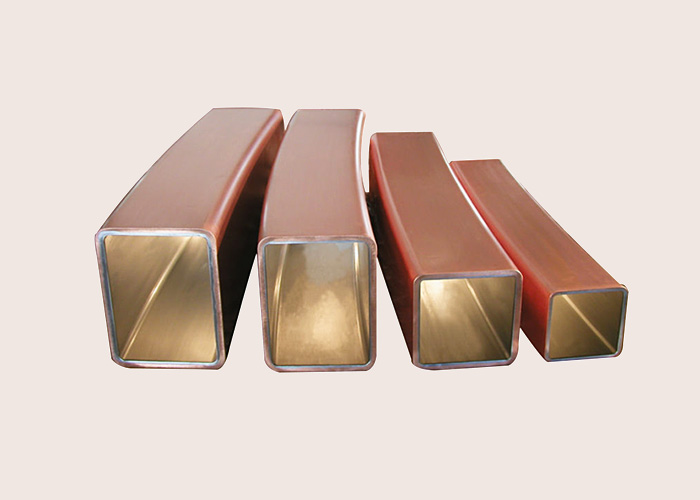

Square Copper Mould Tube

Copper mould tube is core accessories of mould for steel billet continuous casting machine

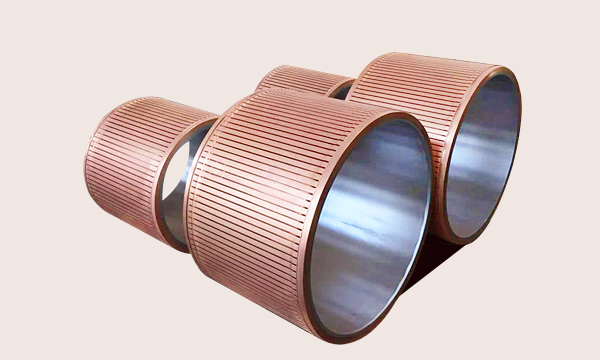

Round Billet Copper

Mould Tube

The rapid development of the iron & steel industry has led to a transformation in the steel manufacturing process.

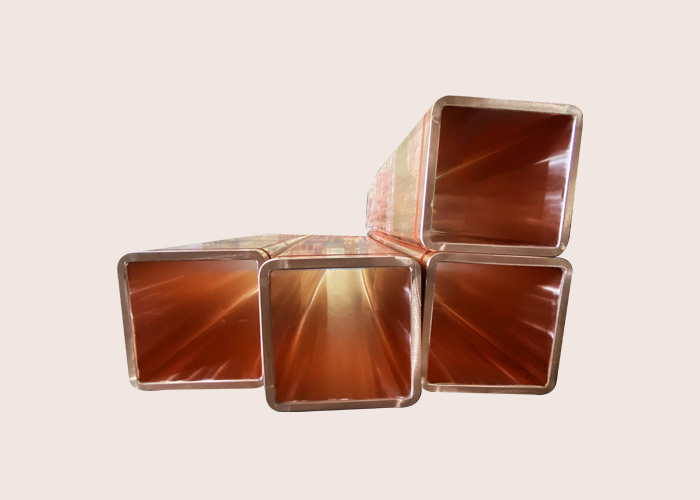

Non-standard Copper Mould Tube

The rapid development of the iron & steel industry has led to a transformation in the steel manufacturing process.

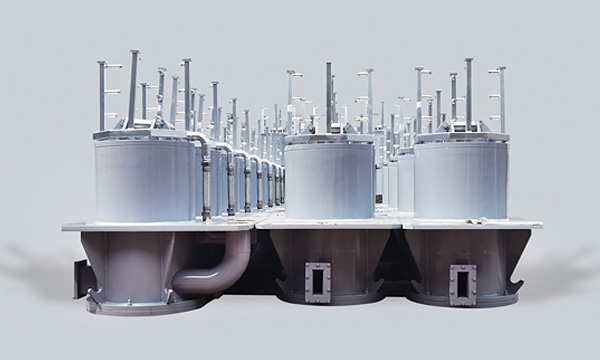

Mould Assembly

Spare parts for CCM/ Crystallizer assembly/ CCM toolings. We can supply all the spare parts which are used in steel plants.

Square Copper Mould Tube

Copper mould tube is core accessories of mould for steel billet continuous casting machine

Round Billet Copper

Mould Tube

The rapid development of the iron & steel industry has led to a transformation in the steel manufacturing process.

Round Billet Copper

Mould Tube

The rapid development of the iron & steel industry has led to a transformation in the steel manufacturing process.

Square Copper

Mould Tube

Copper mould tube is core accessories of mould for steel billet continuous casting machine

About JI Steel

Manufacturer of Copper Mould Tube for Continue Casting Machine

JI Steel Copper Mould Tube plant employs nearly 200 people, manufacturing a wide range of semi-finished, finished and special products for CCM.

JI Steel is committed to research & development, and providing a range of high quality, innovative, cost-effective copper mould tube products and solutions for steel plant.

Founded in 2004,

With 20 years of expertise

in metallurgy industry

Annual production capacity of 30,000 copper mould tube of various specifications, 40,000 rough copper mould tube, 25,000 repaired copper mould tube, and 2,000 sets of mould assembly.

Technical Team

JI Steel has a scientific research and technical team of 20 people and has very rich experience in the metallurgical industry.

Technology Center

JI Steel has an advanced CNC machining center, complete electroplating equipment,advanced electroplating technology, advanced water treatment…

Sales Marketing

JI Steel’s products have been exported to Europe, Asia, Africa, South America and Middle Eastern countries, which enjoys good reputation.

Knowledge Center

LATEST NEWS

Effective communication and collaboration within the team can help harness these qualities and drive the team towards its goals.

2023-8-20

Electric arc furnace top refractory material

The top of the electric arc furnace is generally built with high alumina bricks,

2023-8-30

How to judge the service life of the copper mould tube?

The mould is an important equipment of the CCM continuous casting machine,

2023-9-6

What is the machining accuracy of graphite electrodes?

In order to ensure that the graphite electrode is reliably connected,not loose, not tripped